What is an Anilox Roller?

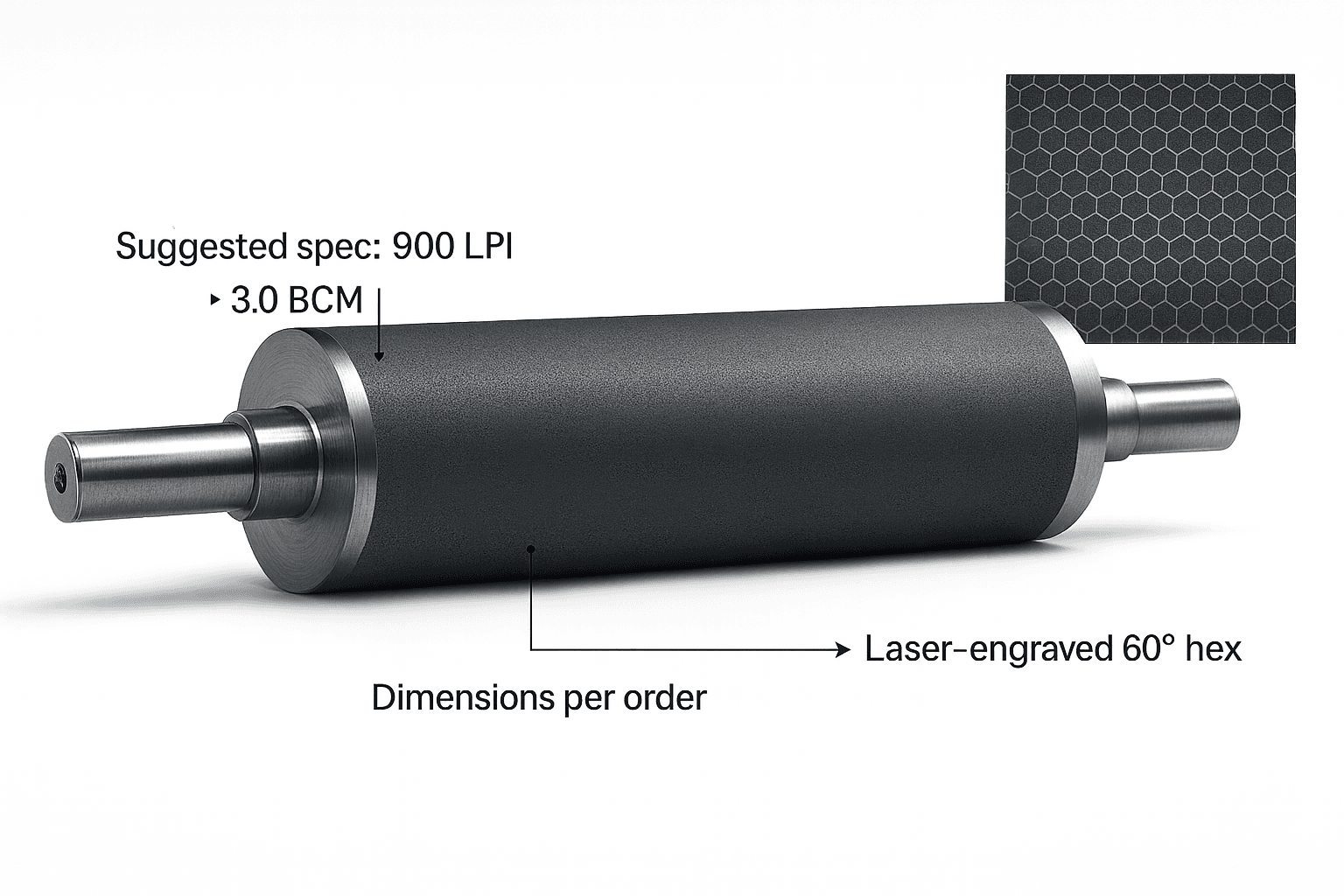

An anilox roller meters ink/coating using a tight pattern of laser‑engraved cells. Cell count (LPI), volume (BCM or cm³/m²) and geometry govern laydown and print quality.

Plasma‑sprayed Cr₂O₃ ceramic (~0.25–0.30 mm), laser‑engraved micro‑cells, specified to your ink, plate screen and press speed. Instant quotations and fast dispatch.

“Sahi volume, sahi print – bina rukavat ke kaam.”

An anilox roller meters ink/coating using a tight pattern of laser‑engraved cells. Cell count (LPI), volume (BCM or cm³/m²) and geometry govern laydown and print quality.

4‑color process with clean highlights and stable tone.

Rich solids and crisp text without over‑inking.

Whites, varnishes & adhesives needing higher laydown.

We finalise LPI & volume after your substrate, plate screen & target density (typical anilox:plate ≈ 6:1). Conversion: cm³/m² = BCM × 1.55.

| Application | Typical LPI | Volume (BCM) | Volume (cm³/m²) | Geometry Note |

|---|---|---|---|---|

| 4‑Color Process (labels/film) | 700–1000 | 2.0–4.0 | 3.10–6.20 | 60° Hex |

| Pantone Solids | 400–600 | 3.0–6.0 | 4.65–9.30 | 60° Hex |

| High‑Opacity White | 200–400 | 6.5–13.0 | 10.08–20.15 | Elongated / HVP / GMX |

| Aqueous Varnish | 250–500 | 4.0–8.0 | 6.20–12.40 | 60° / Open‑channel |

| UV Varnish / Adhesive | 200–400 | 5.0–10.0 | 7.75–15.50 | As per resin/viscosity |

Workmanship & ceramic adhesion warranty for 12 months under normal use. Excludes mechanical damage, mishandling, or scoring from debris/blades. Rapid support for diagnosis and refurbish options.

Check ink pH/viscosity, blade pressure and cell cleanliness. Consider a lower LPI / higher BCM if dots look starved.

Improve filtration and degas ink. For whites/varnish, try elongated cells for smoother flow.

Inspect blade edge & contaminants. Use magnets/filters and reduce excess blade load.

Over‑inking or clogged cells. Deep‑clean; consider higher LPI / lower BCM for process.

We also manufacture press‑ready rubber roller sets for leading offset presses.

Share your job profile and get a tailored anilox spec with delivery timeline today.