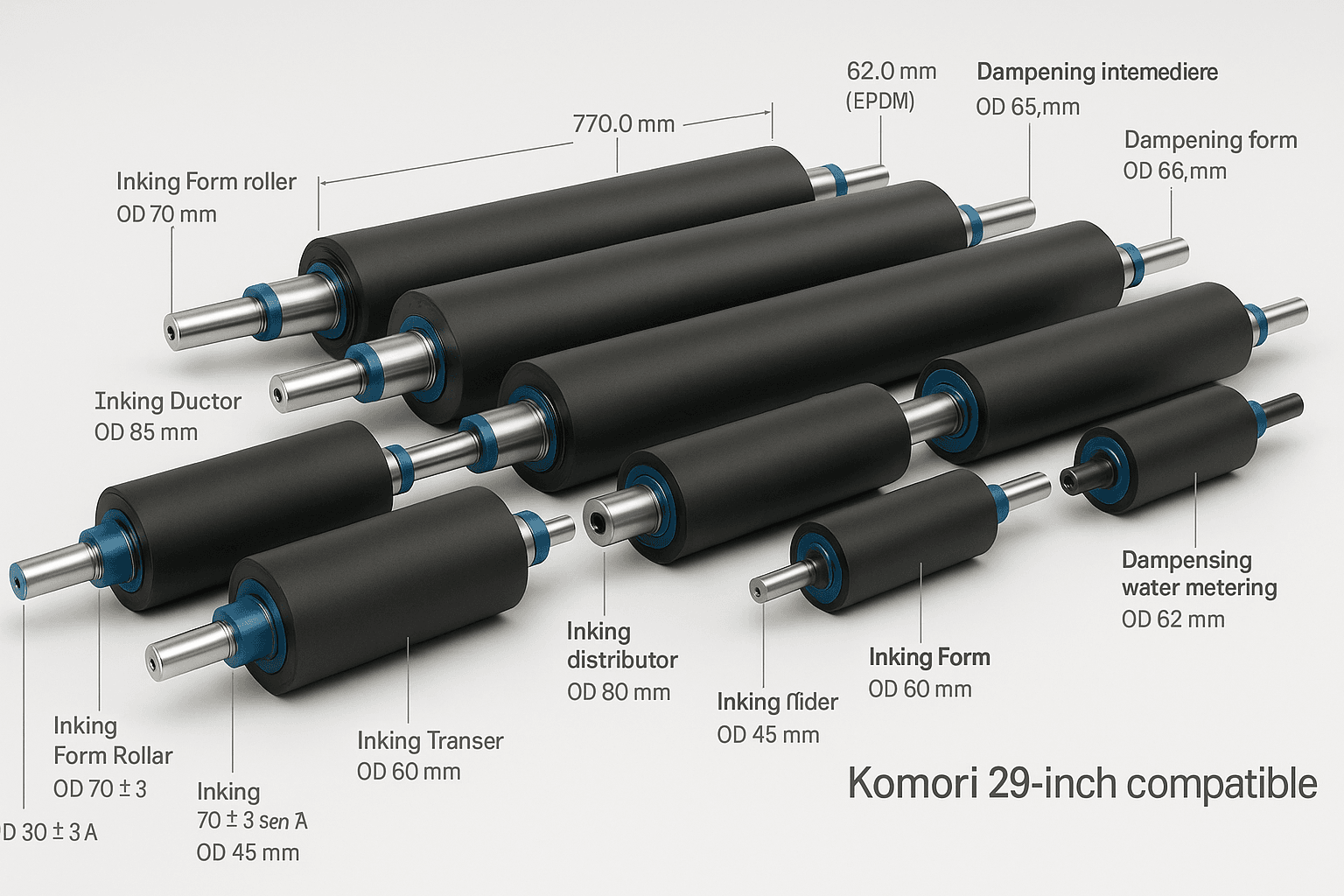

Komori G29 / Enthrone 29 Rollers

Reliable, tight‑tolerance roller sets for Komori’s 29‑inch class presses. Complete inking and dampening sets—precision‑ground and position‑matched for stable ink/water control.

Email: thecooperrollers@gmail.com

At a glance

Complete Sets

Inking, form, distributor, transfer, ductor & dampening rollers.

Tight Tolerances

Precision‑ground OD and balanced nip for consistent ink film.

Compound Options

NBR / EPDM / PU, tuned to your inks, washes & climate.

Matched by Position

Set matching & serial tracking simplify maintenance.

Re‑covering

Re‑cover & re‑grind of existing cores; journal repair on request.

Fast Quote

Share model, positions & quantities for a quick turnaround.

Options & Specifications

Compatible press family

- Komori 29‑inch sheetfed models (e.g., Lithrone G29 and Enthrone 29).

- Share your OEM part list—we’ll map to our set BOM and confirm dimensions before production.

Roller types offered

- Inking train: form, ductor, distributor, transfer, rider

- Dampening: metering, pan, intermediate, form

Materials & hardness

- NBR / EPDM rubber blends

- Polyurethane (abrasion‑critical positions)

- Ebonite & specialty coverings on request

Finish & tolerances

- Precision‑ground surface for accurate nip

- Dynamic balancing & position‑matched durometer

Roller Specifications

Exact dimensions and durometers are matched to your OEM part numbers and press configuration. Values are confirmed before production.

| Position | Material | Durometer | Finish | Notes |

|---|---|---|---|---|

| Form (Inking) | NBR / EPDM | Shore A – matched by unit | Precision‑ground | Set‑matched |

| Ductor | NBR / EPDM | Shore A – confirmed | Precision‑ground | Ink train |

| Distributor | NBR / PU | Shore A – confirmed | Precision‑ground | Wear‑resistant option |

| Transfer / Rider | NBR | Shore A – confirmed | Precision‑ground | By position |

| Metering (Dampening) | EPDM | Shore A – confirmed | Precision‑ground | Fountain solution compatible |

| Pan / Intermediate | EPDM | Shore A – confirmed | Precision‑ground | Alcohol / IPA‑free tuned |

| Form (Dampening) | EPDM | Shore A – matched by unit | Precision‑ground | Ink/water balance |

Detailed Dimensions (per OEM part number)

Provide your OEM part list/BOM and we will populate these values exactly. Dimensions can vary by press configuration and revision.

| OEM Part No. | Position | OD (mm) | Face Length (mm) | OAL (mm) | Journal Ø L (mm) | Journal Ø R (mm) | Durometer (Shore A) | Notes |

|---|---|---|---|---|---|---|---|---|

| EXAMPLE‑123 | Form (Inking) | TBD | TBD | TBD | TBD | TBD | TBD | Example row — replaced after OEM mapping |

Performance Benefits

- Even ink laydown and reduced toning/ghosting

- Faster to target density with stable ink film

- Longer life—resists glazing and swelling

- Less downtime—matched sets reduce post‑changeover adjustments

What to send for a fast quote

- Model & year (e.g., Lithrone G29 / Enthrone 29)

- OEM part numbers or a position list

- Current issues (glazing, toning, slur, gear marks)

- Ink type & wash brand (if known)

- Required quantities (full set / partials)

Service Options

- Re‑covering & re‑grinding of existing cores

- Journal repair & bearings (on approval)

- On‑press troubleshooting support (remote)