PU (Urethane) Rollers

Manufacture & reconditioning to your size, finish, and balance — information‑first page with quick quotation. No direct buying.

Why choose our PU (Urethane) rollers

Printing & Packaging

Offset / flexo / gravure lines — chill, idler, nip/pressure and laminating rolls for stable web tension.

Flexible Films & Converting

PET, BOPP, LDPE and release‑liner webs — guide, laminating and chill rolls with controlled Ra.

Paper & Paperboard

Press, idler and chill positions — consistent finish for sheet and web handling.

Labeling & Narrow Web

Drive / nip / peel‑assist rolls — clean, low‑friction surfaces for precise transport.

Textile

Guide, squeeze and transport roles — finish matched to fabric and chemistry.

Steel & Metals Processing

Coil and sheet lines — robust idlers with wear‑resistant PU (Urethane) surfaces.

Wood, Laminates & Plywood

Press and idler positions in laminate and pre‑press lines.

General Conveying

Feed and transfer idlers for packaging and logistics equipment.

Applications & Industries

Printing & Packaging

Chill, idler, nip/pressure, laminating.

Film & Converting

Guide and laminating with controlled Ra.

Paper

Stable tension and web protection.

Textile

Smooth handling; finish matched to fabric.

Steel & Metals

Robust surface for demanding duty cycles.

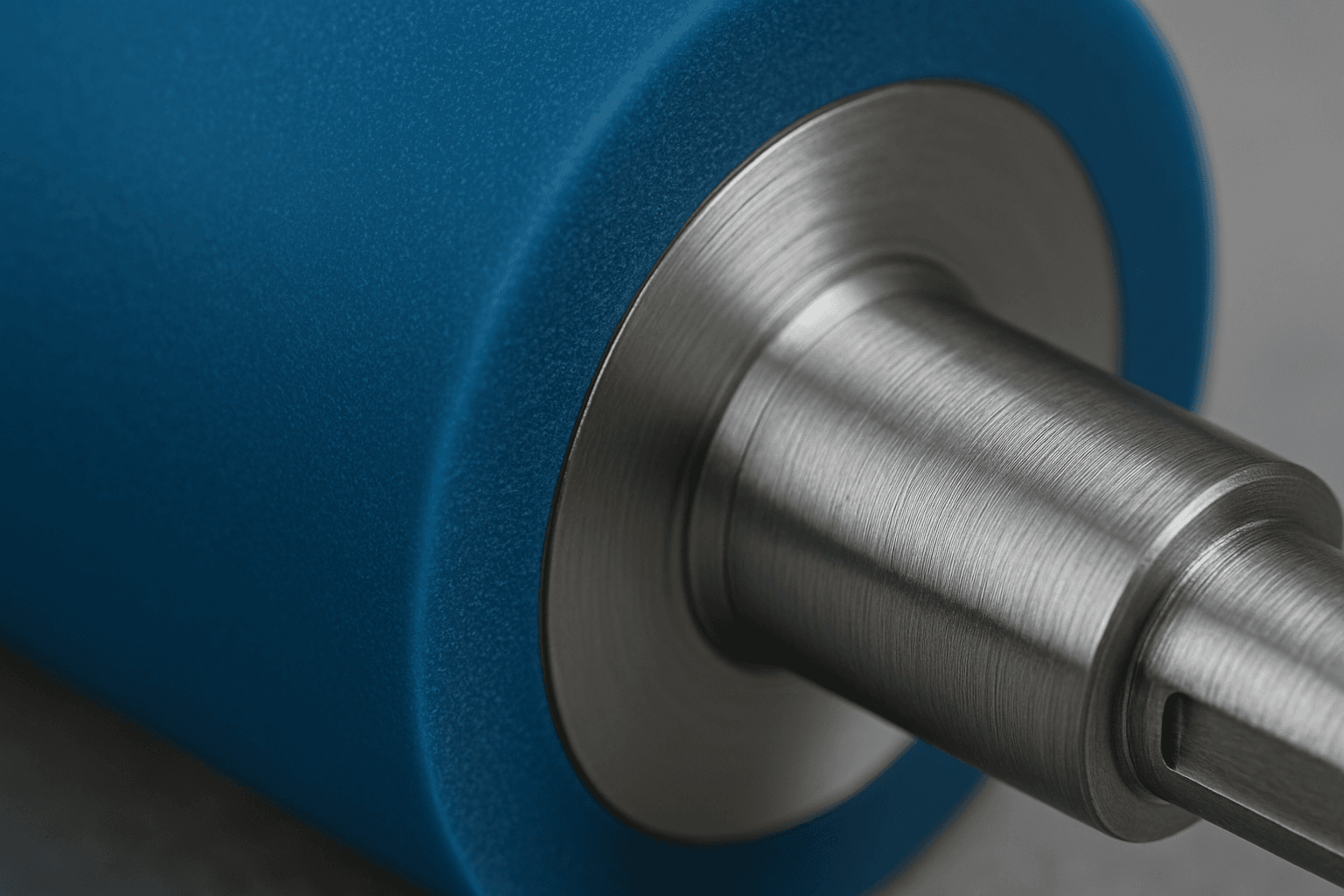

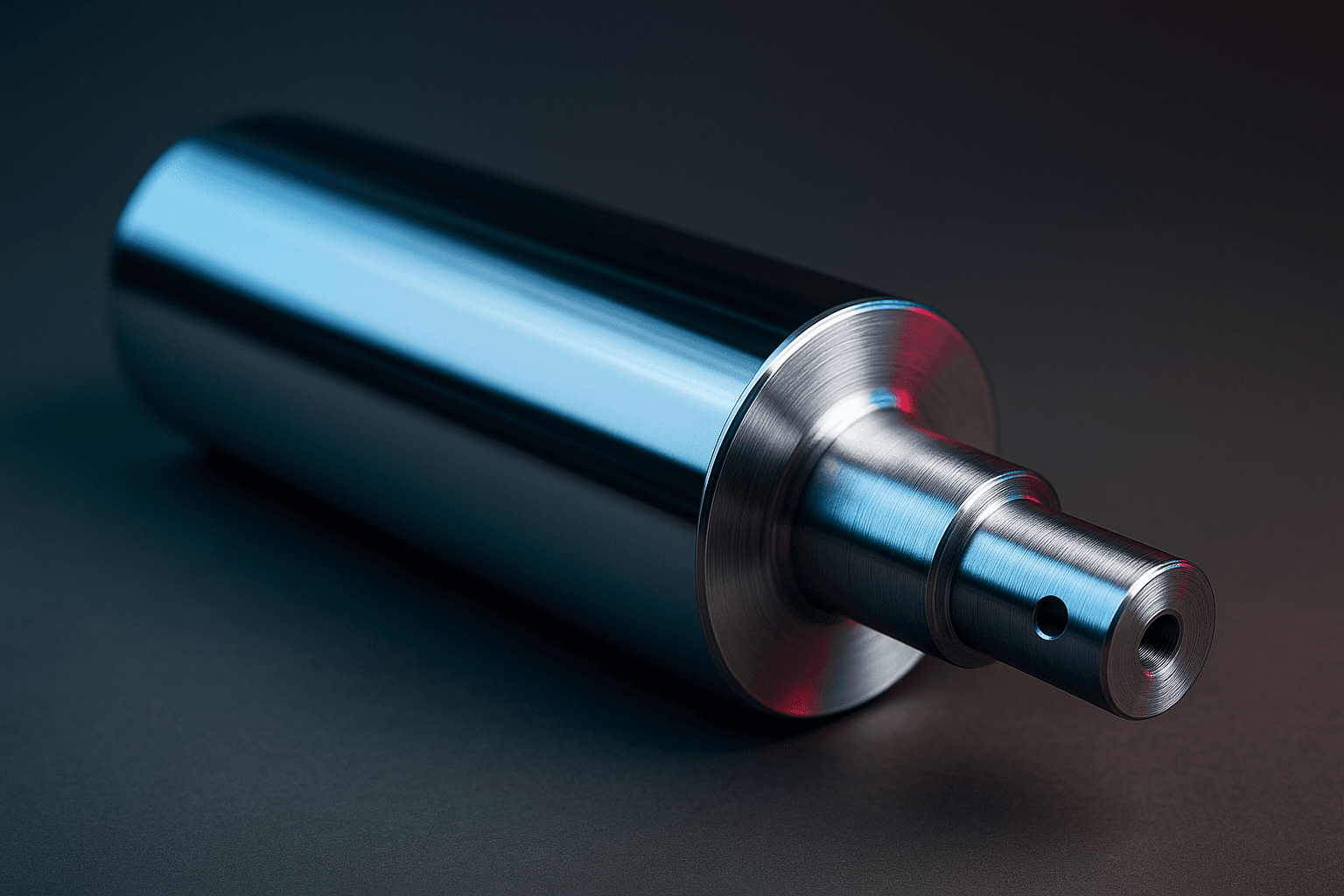

Gallery

Technical Specs (typical ranges)

| Diameter | 60–400 mm (custom available) |

| Face Length | 300–3000 mm (custom available) |

| Surface Finish (Ra) | As specified (e.g., 0.2 μm) |

| Chrome Thickness | Application‑specific (confirmed in quotation) |

| Hardness | High‑hardness industrial chrome |

| Dynamic Balance | Selected per RPM & rotor mass |

| TIR | To your tolerance |

| Core | MS / EN steels / Stainless as needed |

Final values are confirmed during quotation from duty cycle, line speed, and finishing allowance.

Manufacturing & Quality

- 1Build / Re‑chrome

Controlled deposit & adhesion on prepared core. - 2Finish grinding

Super‑finish to target Ra and roundness. - 3Dynamic balancing

Balance level selected for your line speed. - 4Inspection & packing

Runout, TIR, finish checks before dispatch.

FAQs

Can you build to my existing roller dimensions?

Yes — we manufacture to your drawing or sample. Share diameter and face length, shaft/keyway details, tolerances, hardness (Shore/HRC), and target surface finish (Ra). If you don’t have a drawing, we can measure and reverse‑engineer from a sample.

What info helps you quote faster?

Material handled (paper/film/textile/metal), line speed (mpm), roller size (Ø × face), target hardness and Ra, duty cycle, environment (temperature/chemistry), and any balancing or TIR limits.

Typical lead time

Lead time depends on size and workload; we’ll confirm at quotation. Urgent rebuilds can be prioritized when feasible.