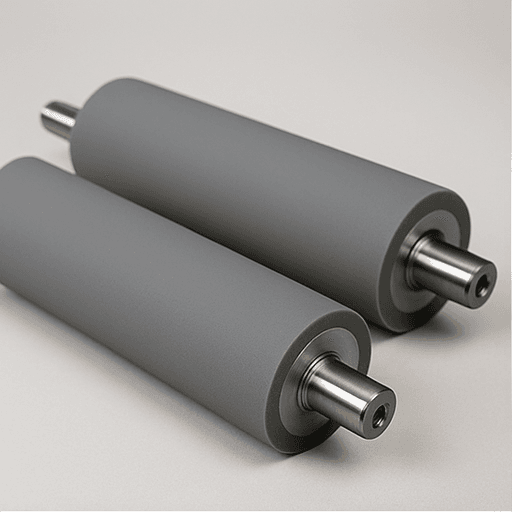

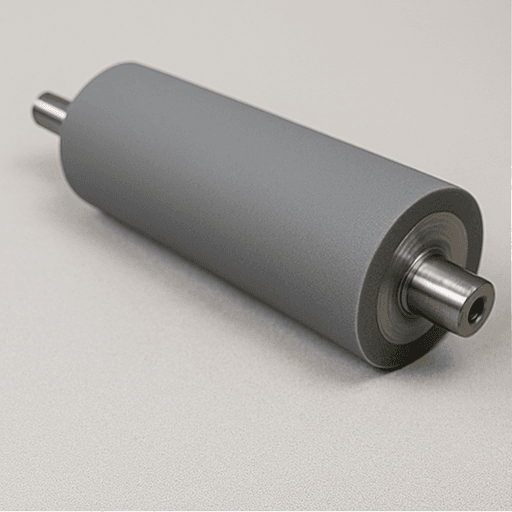

Silicone Rollers

Non‑stick, temperature‑tolerant rollers for release, laminating and heat‑assisted processes. Quote‑only — every order is requirement‑verified.

Why choose silicone rollers

Release characteristics

Silicone’s low surface energy helps reduce sticking in adhesive and coated web paths.

Thermal stability

Handles elevated temperatures typical of laminating and heat‑assist steps.

Clean contact

Smooth, resilient surface to protect sensitive films and treated papers.

Tailored hardness

Commonly Shore A 30–80; we’ll match compliance to load and web.

Bonding options

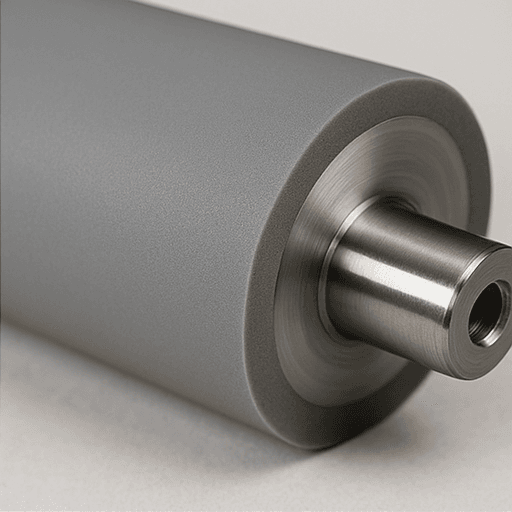

Silicone to steel/aluminium cores with keyed/shouldered shafts.

Recoverable

Re‑cover and re‑grind to restore geometry and finish.

Applications & Industries

Adhesive & Release Liners

Non‑stick contact for pressure‑sensitive labels and tapes.

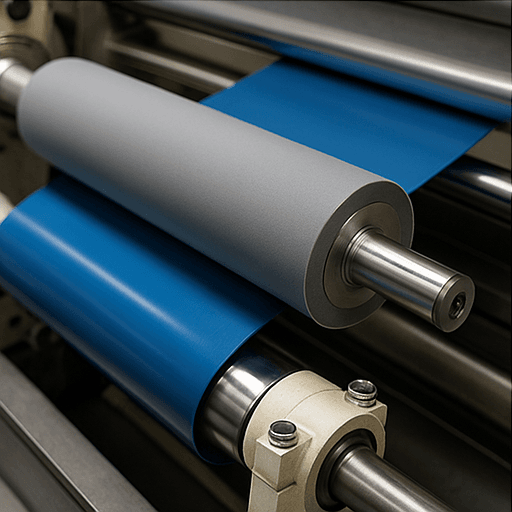

Laminating & Heat‑Assist

Support/pressure rollers where warmth improves bonding.

Printing & Packaging

Web handling where low adhesion is helpful.

Film & Converting

Protective, clean contact on treated films and foils.

Textile

Handling of delicate/treated fabric surfaces.

General Handling

Where release and temperature tolerance are required.

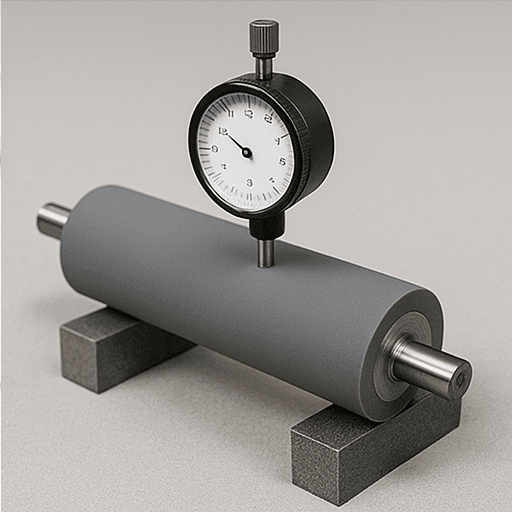

Gallery

Technical Specs (typical ranges)

| Hardness | Shore A 30–80 typical (match to load and nip) |

| Diameter | 20–250 mm typical (custom larger available) |

| Face Length | 100–2000 mm typical (custom longer available) |

| Surface Finish (Ra) | Smooth ground finish; polished options per application |

| Temperature | Suited to warm processes; confirm operating range in RFQ |

| Core & Bonding | Silicone to steel/aluminium cores; keyed/shouldered shafts |

| Balance / TIR | Set to your line speed and tolerance targets |

Final values are confirmed during quotation from medium, speed, temperature and finishing allowance.

Manufacturing & Quality

- 1Build / Recover

Core prep and bonding; silicone covering to spec. - 2Finish grinding

Size to tolerance and texture to target finish. - 3Dynamic balancing

Balance level chosen for your RPM and mass. - 4Inspection & packing

Runout, finish and adhesion checks before dispatch.

FAQs

What info helps you quote faster?

Web/medium handled, temperature, line speed (mpm), size (Ø × face), target hardness and finish, duty cycle, and any balance/TIR limits.

Where are silicone rollers preferred?

Release‑sensitive paths (adhesives/coatings), laminating/heat‑assist steps and handling of treated films or delicate surfaces.

Recover or new build?

We can re‑cover if the core is sound; new build if the core is damaged or a design change is required.